|

Words and Pictures: Rob Bell |

|

|

MGF/TF engine options ... and

alternatives?

|

The 4-cylinder K-series engine: the K4

|

The K4 series engine is the darling of the British sports car industry. Why? The unit is cheap, readily available and modern - but that isn't the whole story. The compelling reason for this ubiquitous unit's success is the engine's weight and size: weighing from 100 to 110kg (from 1.1 8v to 1.8 16v VVC) and measuring 501x630x629mm (LxWxH), the unit is remarkably light and compact. Two exceptionally good reasons to opt for this engine! Add this to the engine's excellent power and torque outputs and good noise/vibration/harshness (NVH) properties, you don't need to be Einstein to figure out why this engine family makes such good sense in so many applications.

Good news for us then that the MGF and TF make use of these excellent power plants in a wide range of guises.

Two capacities of K-series engines have been used in the MGF/TF ranges, all in 16 valve configuration:

|

1.6 litre

|

1.8 litre

|

For the purposes of this engine tuning discussion, we shall restrict our attention to the 1.8 litre variants, although the 1.6 makes for an equally good basis for performance tuning.

Looking at these variants in more detail -

Non-VVC K4 variants: 118 and 135ps engines:

118ps K4

|

|

Fitted in MGF 1995-2002, and TF120, 2002-

Power:

118bhp (120PS) @ 5500rpm

Torque:

118lb.ft (160Nm) @ 3000rpm

Capacity:

1796cc

Weight:

104kg

Cylinder head:

4 valve per cylinder

Inlet valve

diameter:

27.5mm

Exhaust valve

diameter:

24mm

Compression

ratio:

10.5:1

Stroke:

89mm

Bore:

80mm

Cam information:

Inlet: opens 12º BTDC, closes 52º ABDC; lift 8.8mm

Exhaust: opens 52º BBDC, closes 12ºATDC; lift 8.8mm

Valve open duration: 244º

135ps K4

|

|

Fitted in MGTF 2002-

Power:

134bhp (136PS) @ 6750rpm

Torque:

122lb.ft (165Nm) @ 5000rpm

Capacity:

1796cc

Weight:

104kg

Cylinder head:

4 valve per cylinder

Inlet valve

diameter:

27.5mm

Exhaust valve

diameter:

24mm

Compression

ratio:

10.5:1

Stroke:

89mm

Bore:

80mm

Cam information:

Inlet: opens 11º BTDC, closes 61º ABDC; lift 9.5mm

Exhaust: opens 51º BBDC, closes 21ºATDC; lift 9.5mm

Valve open duration: 252º

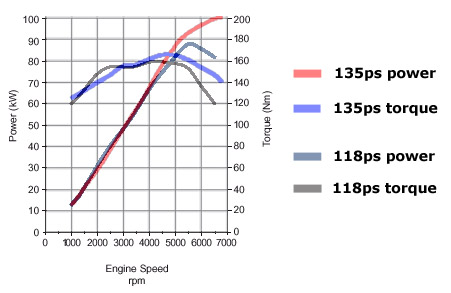

Comparing the 120 and 135ps K4 engines' power outputs:

|

If you study the basic engine specifications listed for the 120 and 135 PS engines above, you'll note that there is just one difference between them: the cam shafts (figures in red). The cams in the 135 are a good deal warmer: 0.7mm more lift and a much longer open duration. The consequence of this is an engine that breaths far better: note how the 135 PS engine produces all those extra 15 horses at engine speeds greater than 4000rpm. Perhaps the greatest surprise is how little penalty is paid in terms of low-engine-speed torque. Certainly some pulling power is lost between1700-2700rpm, but whether this is noticeable out on the road is debateable.

In fact, the 135 cams are a very desirable, and relatively

easy performance modification that can be performed on any K4 engine (the same

cams are used to increase the power of the 110PS 1.6 to 115PS 1.6 in the MGTF).

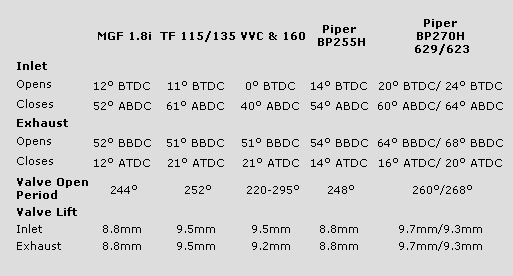

How do they compare to aftermarket cams?

|

The answer to that is surprisingly well (see table, right). The 135 cam has a duration and lift not so far off that used by Piper for their BP270H cam (and certainly a good deal more aggressive than their 'mild road' BP255H).

Therefore, as a tuning modification for a 120PS K-series, these cams make a lot of sense. Even the cylinder head valve springs are the same between all variants (part number LGL10008), at least according to the electronic parts catalogue. However, it has come to light that there is some controversy regarding the suitability of the TF135 cam for use with the LGL10008 standard valve spring. It transpires that this particular spring was originally designed for use with the cams employed on the 1.4 litre K-series. However, Rover's Powertrain engineers found that this cam had sufficient reserves to allow use with the 8.8mm lift 1.8 litre cams. However, whether they'd cope with the 9.5mm lift of the TF135 cam was open for debate (VVC specification springs may be more suitable). The Landrover part number for the up-rated valve spring used in the TF135 is LGL500050, the MG Rover number is LGL000040. This spring has a single yellow stripe and a 3.4 mm wire diameter. LGL100008 has no paint markings (since 1992) and a 3.25 mm wire diameter. However, having said that, the Piper BP270 and 633 cams both have as much or more lift than the TF135 cam, and these were designed for use with the standard LGL100008 valve springs, so from the available evidence it would appear that the TF135 cams can be judged as being 'safe' when used in conjunction with the standard LGL100008 valve spring. This was something that I had intended to confirm on a practical level, but in the end cheated in using complete TF135 valve and spring assemblies.

As an aside - it is interesting to note how similar the 135 cam is to the VVC exhaust cam: the durations are identical - the only difference is that the VVC exhaust cam has fractionally less lift. Therefore, fitting two VVC exhaust cams to your 120PS engine is going to have a significant positive impact upon the engine's performance (if you've done this, please let me know the results!) - and similarly, fitting a TF135 cam in place of the standard VVC exhaust cam may have some benefit - although how much is open to question. Something to try perhaps? Certainly, Piper themselves sell their BP633 cam as a VVC exhaust cam upgrade...

|

Inlet cam assembly: multipoint injection, high Performance: LGC105990 Exhaust cam assembly, multi point injection, high performance: LGC106000 |

If you are interested in

purchasing a pair of '135' cams, then the part numbers shown in the green box

opposite may be of help. These part numbers have come from a search of the parts

catalogue - but there seems to be some anomalies in the naming system and the

prices attributed to the parts, so I'd recommend that you double check with your

local parts department before ordering. However, I am sure that the majority of

you will obtain your cams from the local breakers yard

![]()

Note that for installing TF135

cams into a car equipped with the older MEMS1.9 (post 2001 MGFs and TF use

MEMS3) you will require a distributor drive - Bush-Drive Spindle,

Distributor, part number NJJ10001. The alternative is to cut the

distributor drive from your existing inlet cam: it's your call.

VVC variant K4s: 145 and 160ps engines:

145PS VVC fitted in MGF 1995-2002

|

|

Power:

143bhp (145PS) @ 7000rpm

Torque:

128lb.ft (174Nm) @ 4500rpm

Other specifications as per detailed below for the 160PS engine.

160PS VVC fitted to MGF Trophy 160LE and MGTF 2002-

Power:

158bhp (160PS) @ 6900rpm

Torque:

128lb.ft (174Nm) @ 4700rpm

Capacity:

1796cc

Weight:

104kg

Cylinder head:

4 valve per cylinder

Inlet valve diameter:

31.5mm

Exhaust valve

diameter:

26mm

Compression ratio:

10.5:1

Stroke:

89mm

Bore:

80mm

Cam information:

Inlet:

opens 0º BTDC, closes 40º ABDC; lift 9.5mm

Exhaust:

opens 51º BBDC, closes 21º ATDC; lift 9.2mm

Valve open duration

220-295º

Comparing the 145PS and 160PS engines

|

Pictures taken with the gratefully appreciated assistance of Dave Andrews |

A very reasonable question, when looking at the raw figures of the basic engine specifications above, is how does the 160 engine generate that extra 15bhp over the 145PS VVC? Essentially there appears to be no difference whatsoever between the two engines - so might the difference be in tuning of the engine management map? That may in fact be partly the case, however, there is a significant physical difference in the way the cylinder heads are prepared between the casting used for the 145PS engine, and the 160PS, which is illustrated in the figure opposite.

In the upper picture is shown the combustion camber of the 145PS VVC head. Nothing untoward obvious there. Now compare this with the picture below showing the 160PS head. Here you'll notice that there is a circular ring apparent surrounding the inlet and exhaust valves (highlighted opposite with the arrows to the exhaust valves). What the engineers at Powertrain (MG Rover's engine and transmission arm) have done is to machine the cylinder head concentrically from the valve seat, opening up the combustion camber somewhat. Whereas on the standard cylinder head the valves have quite a 'pocket', this is effectively removed thanks to this simple machining technique, allowing much greater gas flow at small valve openings - as seen at the beginning of the valve open period and towards the point that the valves shut. The consequence is to effectively increase gas flow. Like the gain in power seen on the 135, the increase in power on the 160 is all down to improved breathing.

One question that arises is to why

this clever machining method isn't also applied to the 135 head. The answer to

this is disarmingly simple: there simply isn't the space around the valves to

enable a simple circular machining without going outside the boundary of the

combustion camber and the fire-rings of the cylinder head gasket. As Dave

Andrews points out, the VVC and MPi head castings are quite different, including

the position as well as size of the valves - the position being the most crucial

here, as the MPi valves are much closer to the edges of the combustion chamber.

Shame that.

Alternative K-series power plants: might they fit

into an F?

The normally aspirated K4 is not the sole K-series derived engine in MG's arsenal - there are some very interesting alternatives that are possible, chief amongst them being the K4 turbo (light pressure, as used in the tax-busting ZT160) and the 2.5 litre KV6 (as used in the ZT190). An intriguing question is whether these power plants will fit into the MGF/TFs engine bay. The answer to this is currently not known; but some ingenuity could see either the turbo K4 or even the impressive KV6 installed into the MGF's engine bay...

Turbo K4 160PS: will it fit into an MGF?

The 1.8T engine as used in the ZT160, is an interesting recent development in the K-series engine range. It is a low-pressure turbo application, the primary purpose for which is to provide the ZT range with a fuel efficient, yet reasonably performing power plant that will be attractive for fleet sale. In a car such as the MGF that weighs significantly less than the ZT, this relatively modest engine could provide rather more exciting performance.

|

|

As shown in the picture above (right), the turbo is

mounted on a modified exhaust manifold. Intriguingly, when one compares this

picture to one of Dave Livingstone's engine in its subframe removed from the

car, it does appear that the engine could well fit into the MGF/TF

engine bay. The area that may prove tricky is the subframe, but it is a possible

- and surely it won't be long before someone tries it. Let me know if that

someone is you! ![]()

If you are trying to think of a compelling reason to fit this engine, take a look at the power and torque curves below - compared in this case to the best non-VVC K-series currently available - the 135.

Quite

simply, the 1.8T will blow the 135 away! The turbo engine, despite providing a

low pressure boost, has absolutely masses more torque than the 135 engine. And

the power, of course, considerably greater. With a torque curve sharing a

profile with Cape Town's Table Mountain, this engine will power your MG like a

sling shot, in any gear at any time. A 1.8T in an MGF ought to prove to be an

awesome combination. Even compared to the similarly powerful 160Ps VVC, that

torque curve will give the 1.8T driver a sizable advantage.

Quite

simply, the 1.8T will blow the 135 away! The turbo engine, despite providing a

low pressure boost, has absolutely masses more torque than the 135 engine. And

the power, of course, considerably greater. With a torque curve sharing a

profile with Cape Town's Table Mountain, this engine will power your MG like a

sling shot, in any gear at any time. A 1.8T in an MGF ought to prove to be an

awesome combination. Even compared to the similarly powerful 160Ps VVC, that

torque curve will give the 1.8T driver a sizable advantage.

Given that this engine only weighs in at 114kg - compared to the KV6's 150 (read more below), it makes it a highly suitable addition to the MGF. And because we're talking turbo power here, this engine is going to be a good deal more receptive to 'chip tuning' than the normally aspirated members of the K-series family.

Go on, you know it makes sense!

![]()

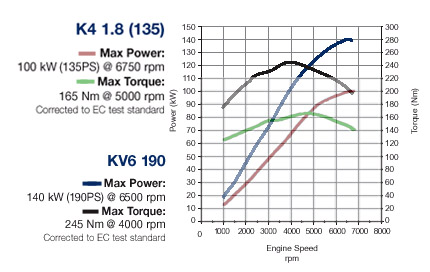

Introducing the KV6 190PS

Comparing the power curves of

the K4 135PS engine and the KV6 190PS mill |

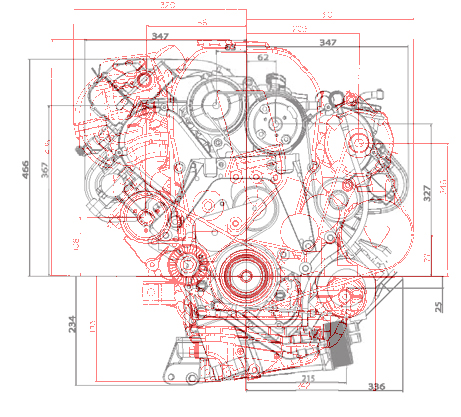

KV6 dimensional figure

overlaying the K4 VVC: not a huge amount in it size-wise |

Back in the 1990s when BAe still ruled the roost at Rover Group, the Powertrain engineers were busying themselves developing the modular engine range we came to know and love as the K-series. In addition to the K4, there was a three-cylinder engine, a V6 and a V8. Although there wasn't an immediate need for some of these engines, the company decided to undertake 'bench engineering' so when the money was available, development of these additional power plants could be undertaken.

Part of that development was the KV6 - a V6 engine with an unusually wide v-angle of 90degrees (betraying the modular design commonality with the proposed KV8 that was never to appear).

The KV6 is now employed in a number of MG Rover cars, including the ZS180, the Rover 75 and the MG ZT190. The KV6 is a very interesting engine; it sounds wonderful and is usefully powerful and torquey. Compared with the 1.8 litre 135PS K4, you can see that the 2.5 litre KV6 is in a completely different league. Imagine that lusty V6 in your MG roadster... hmmm....

The idea is not as far fetched as it may at first seem: the KV6 is a pretty compact unit. Compared with the K4, the dimensions are 498x694x700mm versus 501x630x629mm (LxWxH) of the K4: fractionally wider and taller... so close that it comes tantalisingly close to fitting in the engine bay of the MGF/TF. Very recently, totalMG reported on an enterprising owner who has managed to install a KV6 into his MGF - although the engine bulkhead required modification, and a new, replacement petrol tank needed to be fabricated - hopefully we'll get to learn more as time passes.

However, it isn't all good news. The KV6 190ps engine weighs in at 150kg: the

unit is approximately 40% heavier than the K4VVC. Worse, the weight

distribution and centre of gravity: the impact upon handling could be dramatic

thanks to the way that centre of gravity impacts upon weight shifts under

braking and cornering...

![]()

I have not driven an MGF with a KV6 - but I suspect that such a car would be much closer in character to the MGC: a terrific long distance cruising machine, with a terrifically sonorous, refined and powerful engine; who cares if it isn't as quick witted as a K4 equipped MGF driven at 10/10ths around the Nurburgring?