| Cooling System Modifications |

Whilst we can never truly know the true extent of the head gasket failure endemic in the MGF (and indeed in the Landrover Freelander and Lotus Elise), it is interesting to see that Rover Powertrain Ltd (the company responsible for building and developing Rover's road car engines) had not been sitting on its hands in the latter years of production - and indeed there have been a number of interesting developments in the cooling system department, particularly with the introduction of the MG TF. The most significant of these is the Pressure Relief Thermostat (also known as the PRT) introduced during 2003 for the 2004 model year.

Quick links to features on this page:

the PRT; the remote thermostat

modification; aftermarket remote thermostats;

electric water pumps

The pressure sensitive thermostat

How does the PRT work?

Conventional thermostats - as fitted to all MGFs and early (pre-2003) MGTFs - open purely in response to temperature on the inlet side. As temperature of the engine increases, the thermostat bulb moves to allow flow through the thermostat to permit the entry of cold water into the engine. The PRT is a little different. A PRT thermostat, in addition to opening in response to temperature, will also open its value in a manner related to engine speed - which is rather given away by its name (PR = pressure relief). In effect, this is predicting a temperature rise, as increasing engine speed means that the engine is producing more power, and more power invariably means more heat that the cooling system will have to deal with. This opening of the PRT is accomplished by a simple comparison of inlet and outlet pressure, which is achieved mechanically by a balancing spring. When the engine's water pump spins faster (with higher engine rpm - remember it is mechanically driven off the cam belt) its inlet pressure is pulled down a bit and its outlet pressure rises. Therefore a pressure gradient through the entire cooling system develops and increases as engine speed increases. As the thermostat sits in the middle of that system, it therefore sees a higher pressure difference as speed increases. In order to minimise pump inlet depression the PRT therefore opens at a trigger pressure drop (determined by the aforementioned valve spring) - which for a particular system this pressure drop will be found at a fairly constant engine speed. Different engines will use different springs to suit the application - so using a PRT from a completely different engine will not be advantageous, but one developed for any 1.8 litre K-series ought to be fine for any other...

How does the PRT fit into the cooling system?

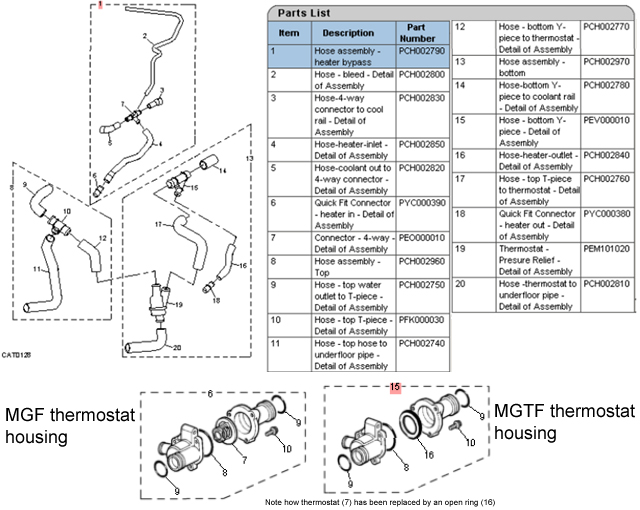

The figure below summarises some of the changes that have come about with the introduction of the TF, and with the pressure sensitive thermostat. It is interesting to note that the original thermostat housing is kept, albeit with an open 'ring' in place of the original 88°C thermostat, whereas the new thermostat is mounted remotely, close to the under body coolant pipes.

|

Installing this new thermostat system IS an option for earlier cars, but the amount of additional pipe work is extensive, and potentially expensive. A more economical answer would be to locate a scrapped TF (or even a later 4-cylinder K-series petrol Freelander that uses the same 1.8 K-series as our beloved MGs) and obtain the complete cooling system from that car.

How do I fit a PRT to my MG?

There are a number on-line guides that cover this, but fitment is essentially straightforward: replace the original engine bay pipes with the new ones, a PRT and ensure that you remove the original thermostat from its housing and replace it with a flow regulator PEL000040A, to ensure that the bypass flow is properly balanced.

Carlo Santeroni, an Elise enthusiast, has an excellent website that covers the PRT installation very nicely for the Elise which is similar (but definitely not identical!) to the MGF that could be used as a useful guide and provides some useful insights into the function of the PRT. Click here to read more.

The Remote Thermostat Modification

An alternative

and potentially cheaper alternative is to mount the thermostat remotely - nearer

the radiator. This has a number of advantages, perhaps chief among them the

reduction in the volume of coolant that is at ambient temperature at the

radiator.

An alternative

and potentially cheaper alternative is to mount the thermostat remotely - nearer

the radiator. This has a number of advantages, perhaps chief among them the

reduction in the volume of coolant that is at ambient temperature at the

radiator.

Other advantages on a practical level include the relatively easy access (pictured right): all you have to do is remove the front bulkhead trim from under the bonnet to view it!

Dave Monk has developed a very simple remote thermostat installation for his MGF, using parts taken from his local scrap yard, and using professional telemetry equipment has shown that this modification works extremely well. I have reproduced his webpage here, as the original (http://www.mgfmavhh.ukf.net/) went off line in 2011. Read more here - along with the tests that prove that it works! We aim to repeat some similar tests on the PRT too...

An aftermarket option that could offer a very similar advantage is the QED remote thermostat. (Thanks to Thierry Zoller for the images below)

|

Remote thermostat kit, as supplied by QED; a very similar kit is offered by Elise Parts - see Engine specialist listing for links |

A close up of the remote thermostat housing |

The remote thermostat kit is the kit that Simon Scutham was instrumental in developing for his racing Elise (see more here).

A rather obvious question is: "Which thermostat option is best for my car?" Unfortunately, I can't answer this at this time, although there are plans to further investigate the thermal cycling problem, and we may look into the relative merits of the PRT and remote thermostat.

The electric bypass water booster pump

|

Another potential cause of head gasket failure is coolant boiling and localised over-heating in the cylinder head once the engine has been switched off and coolant flow drops to nothing.

It is not a particularly common problem on cars used on the road, but those cars that have been adapted for "Fast Road" use or those that partake in track days or competitive motor sport, this problem is more prevalent.

In essence what happens is that once the engine is stopped, the mechanical water pump, driven from the cam belt, also halts. Result: water becomes stagnant in the engine - the only circulation that occurs is due to thermo-siphon. Thermo-siphon was the method of coolant circulation on many pre-war Vintage cars - so quite a reasonable way of moving water. However, modern engines are not designed to make use of this - and the cylinder head on the K-series in the MGF is one of the highest points in the coolant circuit. As hot water rises, this is not an ideal location!

What can then happen in an engine that is very hot, the coolant may actually boil in certain hotspots around the head, despite the high pressure of the coolant system and the 'antifreeze' additives that raise the boiling point of the water comfortably above 100C. When this happens, steam becomes trapped in small pockets, and can corrode or soften the aluminium head and fatigue the head gasket.

So what is the solution? Interestingly, Lotus foresaw problems with the very high performance derivatives (VHPD) of the Elise and Exige. Although Lotus kept the high capacity mechanical water pump (capable of moving over 100L/min), they added an additional 'booster' pump in the bypass circuit. This is pictured above right, and the cooling system with the recirculation pump function is described in the service note reproduced at the bottom of this page.

Unfortunately, the pump available from your local Lotus dealer is prohibitively expensive - something in the order of 150-200 GBP... However, salvation may be at hand in the form of the cheaper Davies Craig Electric Booster pump...

The Davies Craig Electric Booster pump

|

Davies Craig is an aftermarket manufacturer of automotive water pumps, who's current aim is to develop water pumps with the ultimate aim of selling them as OE to manufacturers.

As manufacturers seek ever more ingenious ways of eking out ever better fuel economy from Petrol engines, we may yet see greater adoption of electric water pumps, who's control may optimise warm up, and seek to reduce parasitic losses from the engine.

Thus far, Davies Craig pumps have reportedly been used successfully on a number of 'classic' racers (Triumph Spitfires being one example) and their use so far restricted to the motor sport arena. Might however these pumps be of interest to the "average" MGF/TF owner?

Dave Livingstone and I were originally approached by the UK importer of the Davies Craig water pumps, MAW (http://www.MAWsolutions.com/) who were at that time seeking to receive an endorsement from the MGF Register for the use of one of their pumps in MGs in around 2002-3.

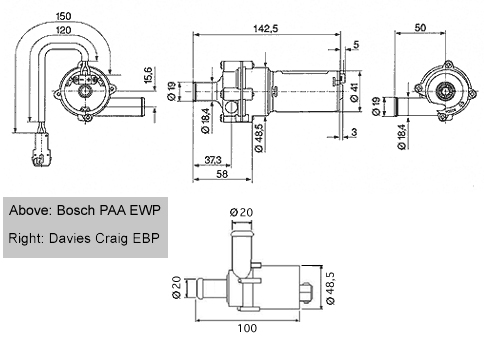

After some research we discovered a staggering similarity between the Bosch manufactured pump specified by Lotus and the Davies Craig electric booster pump (see technical drawings, above). We were suitably intrigued by this, and in collaboration with Tech-speed Motor Sport near Leamington Spa, we investigated the installation of the Davies Craig in a fashion similar to that employed by Lotus (installation figure for electric water pump, AK117K0013F, above).

|

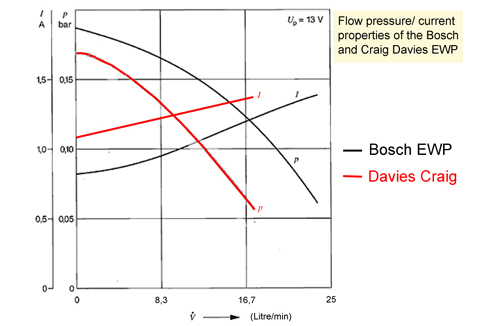

The original pump, as supplied in 2003 was not quite the same as the pump specified by Lotus. Whilst both pumps work on 12volts over a similar current range, and work at the same peak pressure (10kPa, or 0.1bar), maximal flow characteristics show that the Bosch is capable of pumping 20L/min against the Davies Craig EBP's 13L/min.

A comparison of the two pumps current/ pressure/ flow characteristics are shown in the figure opposite. The question was: are these differences going to have a dramatic impact upon the effectiveness of a Davies Craig pump on heat soak following ignition-off?

For the Lotus application, the electric water "recirculation" pump would "kick in" if the engine coolant temperature was above 110°C and the ignition was switched off, for up to 20 minutes or until the coolant temperature dropped again to below 100°C. The radiator fans would be initialised if the coolant temperature exceeded 120°C. Unfortunately, the engine ECU is different to the MG-Rover MEMS in later Elise variants, being more extensively modified by Lotus. Therefore for our application, we extensively simplified the operation of the pump such that it was controlled using a simple timer, triggering when ever the engine was switched off and running for a pre-set duration (typically around 5-10 minutes).

Initial findings:

Despite initial anxieties regarding the difference in water flow, we found some very encouraging data following rolling road sessions using an infra-red probe on the coolant outlet pipe from the cylinder head. Following each power run, we would switch off the engine while the car was still on the roller, and measure over time the temperature at the cylinder head. Interestingly with the electric pump running, the cylinder head outlet pipe would get much hotter than with it off, showing that heat was being actively removed from the cylinder head. This was very encouraging data showing the efficacy of this heat removing strategy following engine switched off and the electric water pump was left to its own devices. It looks to be an effective solution from this measurable end point.

In 2015, we hope to look at this project again, especially as the current Davies Craig water pumps have flow characteristics much closer to to the Bosch pump originally specified by Lotus. Using more more sensors under more varied circumstances, we want to see whether the electric booster pump is an effective solution for road and motor sport MGs. We may also be able to take a look at the Davies Craig water pump as an alternative to the mechanical water pump. This could be a very exciting project: more information as we get it.

Water pump logic, and general cooling strategies - as used by Lotus on their

K-series VHPD-powered cars - is shown below...