|

Part 19:

No time and no moneyI think that there is a law of entropy that applies to car enthusiasts and car projects that says that when you have money, you have no time, and when you have time, you have no money. The net result being that invariably projects progress at a slow rate whatever circumstance you encounter. Well, I have hit a double whammy of no time and no money. Well, not enough money to jump the final hurdles that could see Project Shed on the road for the first time with any great speed at any rate. Invariably that has lead to a substantial slow down in the rate of progress that I had hoped to make in the opening months of this year and why the last update on the project was 6 months ago (oops). And once again I have missed the deadline for the Silverstone Sprint at MG Live (2013)…

What’s needed for the final finish

There are a few jobs needed to be done before Project Shed could be considered MoT compliant – the seat belts, screen heaters and a rear view mirror being three quite simple things to sort out. I also needed to take out the windscreen wiper mechanism again and either attempt to service the corroded motor, or replace it. But the car also needs fresh tyres – and let’s face it, four new rubbery doughnuts aren’t the cheapest purchase in the world (I’ll be avoiding Pirelli in case anyone asks, given their recent performance at the Silverstone F1 race). Tyres are particularly not cheap if buying grippy rubber for track days and competitive motor sport. I’ve got some old Goodyear Eagle F1 GS-D3s on the rims at the moment, but they must be at least 7 years old, and thanks to previous track use, are rather worn over the shoulder. But just enough tread for an MoT because, surprisingly, there is still decent tread covering the MoT-critical centre 2/3 of the tyre. Even so, old, hard rubber isn’t the best option for road use, let alone for the track! That’ll be a few hundred quid then to get these replaced by rubber that is halfway decent. Gulp. I also need to do some more research and find which tyre is the best fast-road option since my beloved Bridgestone S-02 (and still the best road-tyre I have ever used on an MGF) have been unavailable for a number of years now. Or do I just go straight for road-legal track tyres? Decisions, decisions…

First things first

If the Shed were to ever to pass its MoT, it would need those little detail items dealing with. The rear view mirror first then. For as long as I have had possession of the Shed, it has never had a rear-view mirror. I am not sure why, but the metal shoe that the mirror attaches to on the windscreen was missing – I am not sure whether it had fallen off due to "Natural Causes" or was yanked off during its somewhat brutal strip down before I had collected it. In any case, let a problem become an opportunity: I could save weight and put the mirror in a slightly better position given that the car now has a roll cage and a lower seating position than before. Logging onto the internet I found what I thought was the cheapest suction-cup rear view mirror I could find. I bought this from Amazon and they delivered two of them on successive days. Odd; I only ordered one?

It’s often said that the cheapest parts are the most costly (because they won’t work, and you have to pay to replace them again). That old adage had real potential to be true here, because the cheap suction pad did not adhere to the inside of the windscreen for any period of time longer than 30 seconds. A rear view mirror that only provides a view of the sky while rattling around in the foot well is no more useful than a chocolate tea-pot: I left a rather negative comment on the Amazon feedback form. Again, perhaps I could make something of this mirror? As I mentioned, there is a roll cage there as a useful mounting point. I had previously researched the option of buying a rear view mirror that attaches directly to the roll cage, but the only ones I could find were in the United States and they weren’t particularly cheap. Nothing with "Motor sport" in the title ever is. However, a jubilee clip will nicely clamp the cross beam of the cage behind the windscreen’s header rail. So I cut off the useless suction cup from the mirror, crudely bent an off-cut of aluminium into a "U"-shape, tucked this inside the jubilee clip, and used self tapping screws through either side of the "U" to hold the mirror in place. The rear view mirror is now very secure and stays where you leave it. Job done. It doesn’t have a dip switch, but since Project Shed won’t be going night racing, I don’t perceive this to be a problem.

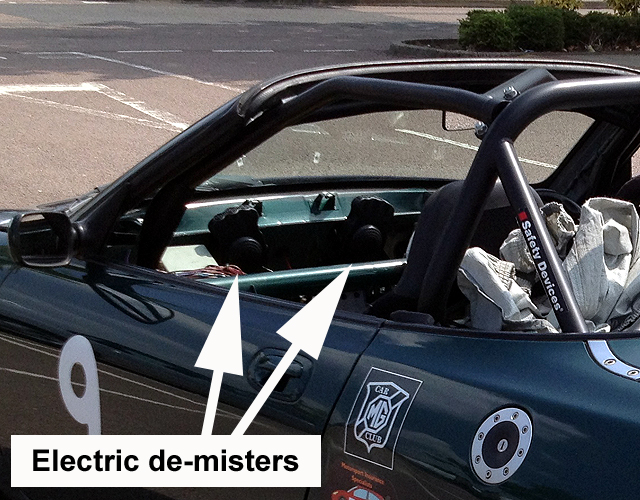

Windscreen demisters next. I mentioned in the last instalment that I’d bought a pair of what are, effectively, 12 volt hairdryers. No, they are not the most effective things on earth, but they get the nod from Mr MoT inspector, so from that perspective, they’ll do the job. So I have now fitted them with self tapping screws to the front bulk head under the windscreen and have taken the power from the rear heated window circuit that is present on all of our MGs, but now redundant on Project Shed. Happily, the car that I had salvaged the wiring system from had clearly been fitted with a hardtop earlier in its life, and so the Shed had the prerequisite relay. Those with long memories will recall that I had fitted a heated screen switch to the fabricated auxillary panel ahead of the gear lever. So now, once the engine has oil pressure (and therefore running and charging the battery), I can switch on the demisters by depressing the heated rear window switch: it works a treat! I have yet to try it out on a misted windscreen, so how effective it is in terms of demisting rather than simply making a whizzing noise remains to be seen…

Non-exploding seat belt buckles were the next stop. As you’ll know, the buckles built onto the standard seats are packed with pre-tensioning explosives. The SRS system has been removed from Project Shed, so now these fun-sized explosive devices were as welcome as a swarm of angry wasps in a nudist camp after a jam fight. You will also be aware that there were no standard-fit, non-exploding seat belt buckles available for the MGF. But you know as well as I that the MGF is a parts bin special – and this has a number of significant advantages when going off-piste during a rebuild. Having ready access to both a ZS and ZT, I already knew that neither of these cars had similar buckles to those found in the MGF. However, aficionados (a nice way of saying "nerds"?) will know that the MGF draws most heavily from the Metro and Rover R8 Rover 200 parts cache, so I asked Gary, the next time he visited his local scrap yard, to pick up a brace of rear seat belt clasps. I’d pretty much convinced myself that the "Bubble" shape R200 rear belt buckles were identical to the MGF’s, but it was still a punt… and it paid off! They fitted perfectly to the standard inertia reel belts on the car! So the next question was where to mount them. This was a good excuse to sit in the car and ponder for a while, and in the end, I used the same pick ups as the 4-point harness eyes that Keith had welded in when Project Shed had last visited the Mill, Tech-Speed motorsport’s base in Eathorpe, near Leamington Spa. There is a bit of faff-factor trying to click the belt on because of the high-sided racing bucket seat, but over all I am very pleased that the assemblage of parts works as well as it does.

Finally to deal with the non-operating windscreen wiper motor. Its function was intermittent and it was really noisy: think of a cement mixer full of old bolts, and you get an idea of what this motor sounded like when it worked. Ah yes, when it worked. Which was when it felt like it (and that wasn’t often). The noise and intermittent operation I figured was down to water ingress. The motor’s bearing race had almost certainly suffered corrosion, and everyone knows that electrics don’t like water. So replacement was in order. The initial plan was to swap the single wiper conversion from my other MGF to the Shed, and revert that car back to standard twin wipers. It was all starting to sound like a bit too much work and in the end it was much easier to simply swap over the motor from a spare wiper mechanism straight into the Shed. Happily, now the wiper works smoothly and quietly. But still intermittently. Odd. Charlie, my 5-year old son, cracked this problem by kicking the fuseboard: a loose or dirty connection! Good work Charlie: fixes don’t come easier than that! Annoyingly however, the intermittent non-operation was going to come back to haunt me later…

Registration and the DVLA

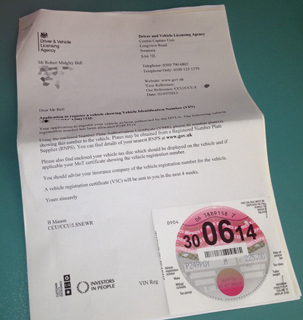

There were a number of steps required to get the Shed road legal and registered. As long-time Shed watchers will know, the Shed was originally registered in Guernsey, and although shipped to the mainland (and officially exported from Guernsey) in 2006, it appeared that no effort had been made to officially import and register the car officially in the mainland UK. So the plan went something like this: (1) get the car insured on its chassis number and take Project Shed for an MoT; (2) obtain MoT certificate; (3) send off details to HMRC and pay any VAT due on a car imported from the Channel Islands; (4) HMRC complete what is known as a NOVA (Noticification Of Vehicle Arrival – or something like that) which will then be sent to the DVLA. (5) Once the NOVA has been completed, and any monies owing have been paid, send all the details off to the DVLA in Swansea (Vehicle Importation Unit) who, on relieving you of £225 annual road tax and £55 vehicle registration fee, will issue you with a new registration number and a fresh tax disc! Yay.

Insurance

Let’s tackle the insurance first. It’s a modified road car with track use in mind. The roll cage is a bit of a give away here. This kind of car clearly gives many insurance companies the heebie jeebies. They don’t want my business – so I’ve contacted a number of specialists, starting with Adrian Flux, who have a reputation for insuring modified cars competitively. But not for my modified MG it seems: for third party fire and theft for my car parked on my driveway and a 1500 mile annual mileage limit, Adrian quoted a staggering £660. OMG! I was feeling depressed. I had to make myself to pick up the telephone to get the next quote. A-Plan Insurance has an MGF specialist office, and these nice people were my next port of call. I also decided to get a quote for the Shed to be garaged as well as for being parked on the driveway. A quotation of over 440 quid, garaged was the response from their insurer who also insures my other F. Certainly better, but unless I was going to get a quote for under 400, I reckoned I might as well be better off with a trailer and forgetting this whole road registration idea. I needed some inspiration – so I contacted my friend Tim Woolcott to see who he insured his track-prepared Caterham with. Richard Egger Insurance Services (or REIS as they’re now known) was his reply, so I dropped them a line and got them to quote for both garage and drive parking: £295 and £340 respectively. Wow, that was a LOT better. Around 300 quid is borderline-affordable…

Going for the MoT

So, having got the car insured on the chassis number, the next step was to take it for an MoT. The MoT regulations have changed and tightened-up recently, so I was interested to see how they handle a track orientated MGF. Surprisingly well as it turned out. I pre-empted some trouble using the general MoT rule of "if it is there, test it" and turned it around: "if it isn’t there, they can’t fail you" – so there is no spare wheel, no inflating gunk (I’d bought some just in case, but further research had revealed this to be unnecessary), no window mirror switches (I haven’t made a switch panel for this, owing to my procrastination as to whether I want to do away with the heavy motors or not). There is no seat adjustment (well, there is, but you’d need a spanner) and no airbags. Interestingly, the MoT guy appeared not to notice the disappearance of the SRS warning lamp (or indeed the airbags etc) – but since the binnacle illuminates all the other lamps in the usual way, I am sure he didn’t notice the absence of the SRS… and perhaps they also recognised the motorsport orientation of the car and made due compensations in light of this.

I have to say that going for that first MoT was pretty exciting. I decided to refit the one Guernsey number plate I had (hello again, 18890!) as I figured it would be a good idea to go for a quick "Italian-tune" on the way to the MoT testing station in order to get the catalyst up to temperature and burn any residue off and thus give the car its best chance of a first-time pass. A car with one number plate is surely less suspicious than a car with no number plates whatsoever? And boy, was it a hoot to drive the Shed on a public road for the first time! I dropped the car off at the MoT centre. The guy doing the test was a good deal taller than my 6ft frame. Didn’t I mention the non-adjustable seat and a roll-cage? The car is tricky enough for me to get into and out of, and this guy ended up having to sit on rather than in the car… more to my amusement than his I think!

Did it pass? Is the Queen a Transvestite Shepard from Woking?

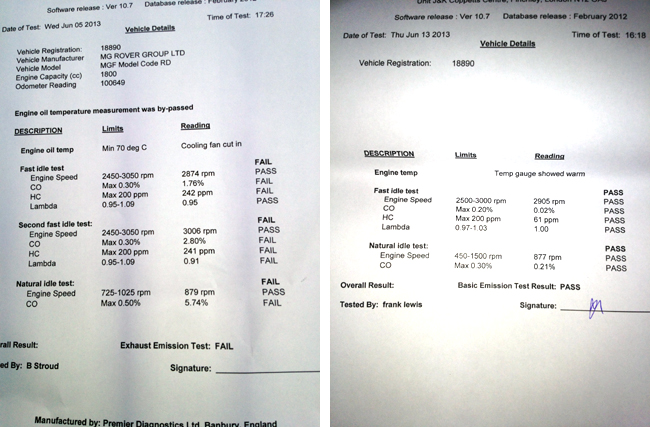

Did the car pass first time? Nope, but it was remarkably close, much to the general surprise of everyone except me (it doesn’t necessarily give the best first impression, the Shed, but looks aren’t everything!) Somehow it had blown a bulb on the way to the testing station (I’d checked and double checked all these things before I had set off). And I mentioned the intermittent function of the wipers? Well, it chose to work not at all for the MoT test. Just brilliant. But that wasn’t the biggest fail. Nope. The big fail was reserved for emissions. Too high hydrocarbons, too high carbon monoxide and a lambda reading that seemed inappropriately low. I am surprised how quick everyone was to blame the catalyst, but this was a "new" one that I had picked up of Richard Jones, so I’d be annoyed if the catalyst, that on previous visual inspection had looked entirely fine, was up the spout. But I recalled that I had needed to change the lambda when fitting the exhaust, and that I’d also had to change the connector, so what I’d had to do was solder the old lambda sensor harness connector to the new lambda sensor. For what ever reason, I’d always had misgivings about this, and instantly, on receiving the fail certificate, I was looking on the Bay-of-E to find a replacement. An internet search also revealed the Lambda sensor as a likely candidate for this particular pattern of abnormal emissions readings, so a couple of mouse clicks and a day or so later, a fresh, OEM Rover lambda sensor landed on my door mat. Changing it was a doddle – as the "old" lambda had not had a chance to corrode in place and so was quickly changed. A re-test was booked and the car sailed through its emissions test.

What of the wipers you may be wondering? An oxidised connector on the fuse board I think. A bit of vigorous wobbling and pushing in and out seems to affected a cure (for how long I don’t know, but it’s currently still working).

HM Revenue and Customs

At the time of the first test, I had submitted my application to the HMRC for importation of a personal motor vehicle. It was slightly embarrassing to admit that the car had been imported in 2006 and it was now 2013 (what had it been doing for the last 7 years?), and that I had no idea who had originally imported it into the UK. However the appalling state that the car was in worked to my favour: it enabled me to put a scrap value on the car at the time I collected it, and the tax man took the same view as me that the car was indeed scrap. I think he said scrap – but it might have been "scrap" with a silent "S". Getting all the paperwork that HMRC wanted took rather longer than I’d have liked – indeed, by the time that they approved the NOVA, 3 weeks of my temporary insurance had expired. The friendly people at REIS helpfully pointed out that if I did not provide them with a registration number within the 30 day limit, they would cancel the policy and I’d be liable to a 50% cancellation fee of the whole year’s policy value. Oh. Dear. Grief.

V55/5

The importation document that the DVLA requires you to

complete to bring a car into the UK is called the V55/5. It’s one of those

wonderful, classic DVLA overly complicated forms, but thanks to the Shed having

originally manufactured at the end of 1996 (and therefore before 2001), I didn’t

need to complete all the homologation information with all the attendant

emissions data. Phew! Good news! So as soon as I had email confirmation from the

HMRC that they’d completed the NOVA, I put the V55/5, and all the necessary

documentation (proof of identity, insurance, MoT, cheques, Guernsey certificate

of export etc) in first class, recorded delivery. Thereafter followed a rather

fraught few days with frequent telephone calls to the DVLA to try and ensure I

got the registration details before I was punitively charged the insurance

cancellation fee. The DVLA, to their credit, completed the registration within 3

working days (which is their target) and sent the documents by post back to me.

Unfortunately by Business Post – which takes 3-5 days. Argh! Did I get the

documentation in time before the expiry of the temporary cover note? Nope. But

luckily, the very nice people at REIS felt sorry for me and left the file open

for an extra day, and lo and behold, the DVLA registration documents fell

through the letter box the very next morning, 31 days after my first applying

for the insurance and the first attempt at the MoT.

Welcome, P249 POY!

So now Project Shed has a new identity, P249 POY. It has a valid tax disc showing in the windscreen (possibly for the first time in nearly a decade), new number-plates front and rear, and is fully road legal. Wow! I can now do some road testing, and I have booked a track day in October (Donington) which I am really looking forward to. I may also enter what remains of this year’s MGCC Speed Championship – although I need to get the fire extinguisher serviced and I need new tyres, and ideally I need some way of keeping dry… So yes, the Project Shed build saga is not yet over! But it is very nearly at the end of stage one.

Here’s looking forward to Project Shed, part 20!