Electric Water Pump

|

Cooling System

Modifications: Electric Water Pump |

The electric bypass water booster pump

Boiling and cylinder head cavitation

|

Pitting caused by localised boiling on a car that was driven exclusively on the road. The head had to come off for other reasons and this damage was spotted incidentally. |

One potential cause of head gasket failure and an important cause of cavitation in an alloy cylinder head, is coolant boiling. Because the K-series, like any other current series production engine, uses a mechanical water pump to force the coolant around the engine and out through the radiator and back, the coolant is most prone to boiling after the ignition has been switched off; heat continues to dissipate from the still hot combustion chambers, but now has nowhere to escape other than into the now stagnant coolant. What can then happen in a very hot engine is the coolant may actually boil in certain hotspots around the head, despite the high pressure of the coolant system and the 'antifreeze' additives that raise the boiling point of the water comfortably above 100C. When this happens, steam becomes trapped in small pockets, and can corrode or soften the aluminium head and fatigue the head gasket.

As a cause of gasket failure on road cars, it is very hard to know how much of a problem this is over the very long term - but one supposes that it is not a particularly common problem on cars used 'conservatively' on the road. But those cars that have been adapted for "Fast Road" use, or those that partake in track days or competitive motorsport are bound to be more prone to this problem.

Is it possible to stop coolant boiling from occurring?

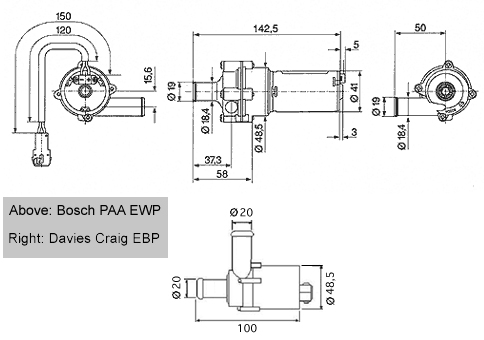

Lotus fit a coolant re-circulation pump to all its cars fitted with the K-series VHPD engines. This solution involves the insertion of a Bosch water pump in the bypass circuit - as is shown in the figure above. |

So what is the solution? If coolant boiling only starts once the water circulation stops, then the obvious solution is to maintain that circulation once the engine is switched off. The logical option, therefore, is to fit an additional, electric powered water pump. So the search is on for a suitable water pump - and where best to put it.

No need to re-invent the wheel...

Interestingly, Lotus foresaw problems with the very high performance derivatives (VHPD) of the Elise and Exige. Although Lotus kept the standard high capacity mechanical water pump (capable of shifting over 100 litres of water per minute), they added an additional 'booster' pump in the bypass circuit that is controlled from the ECU and is switched to come into operation once the ignition is killed. The Bosch water pump used by Lotus is plumbed into the coolant bypass circuit, as pictured right.

That the Lotus Elise and Exige use what is effectively an identical cooling set up to the MGF and TF is useful for anyone considering a retro-engineered solution from one marque to another.

It therefore makes a lot of sense to use a system that someone else has invested research and development time and money into. Unfortunately, the pump available from your local Lotus dealer is prohibitively expensive - something in the order of 150-200 GBP... However, salvation may be at hand in the form of the significantly cheaper Davies Craig Electric Booster pump...

The Davies Craig Electric Booster pump

|

Davies Craig is an aftermarket manufacturer of automotive

water pumps, whose current aim is to develop water pumps with the ultimate aim of selling them

as Original Equipment to manufacturers. Unfortunately, the capacity of electric water pumps have not yet

reached the level achieved by engine-driven mechanical pumps on modern engines, although

Davies Craig pumps have reportedly been used sucessfully on a number of 'classic' racers

(Triumph Spitfires being one example). Dave Livingstone and I were approached by an

importer of the Davies Craig, MAW (http://www.MAWsolutions.com/)

seeking to receive an endorsement from the MGF Register for the use of one of their pumps

in MGs. We weren't entirely happy to do this without proper consultation with specialists

- and we felt that their then solution could be improved. A little more research however

indicated a staggering similarility between the Bosch manufactured pump specified by Lotus

and the Davies Craig electric booster pump (see technical drawings, opposite right)... We

were suitably intrigued by this, and in collaboration with Tech-speed are currently

investigating the installation of the Davies Craig in a fashion similar to that employed

by Lotus...

|

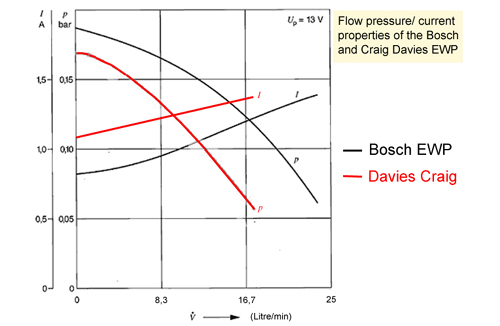

It is not complete plain sailing however, as there are some important differences between the two pumps. Whilst both pumps work on 12volts over a similar current range, and work at the same peak pressure (10kPa, or 0.1bar), maximal flow characteristics show that the Bosch is capable of pumping 20L/min against the Davies Craig EBP's 13L/min.

A comparison of the two pumps current/ pressure/ flow characteristics are shown in the figure opposite. The question is: are these differences going to have a dramatic impact upon the effectiveness of a Davies Craig pump on heat soak following ignition-off?

The answer to this is "we don't know - but let's give it a go, as something is surely better than nothing!" However, in terms of value-for-money and establishing whether a modification is worth while or not, we are going to need to do some testing - more of this later.

Water pump logic - as used on the Lotus pump - is shown below...

The Jig-Saw is nearly complete...

So we've now got to a situation whereby we have a suitable and affordable water pump, a method of installation, and the logic of how to control that water pump in the car. It should now all be very straightforward shouldn't it? Not quite. It is still not clear as to whether MEMS is capable of undertaking the operation of the water pump as described in the Lotus notes - especially as Lotus VHPD engines use a different engine management system to that found in other Lotus' and MGs. Trying to find out more information from the technical experts at Powertrain Ltd lead to a considerable loss of time without a definitive answer - so in the end, we all decided that making our own electronic control module would probably be the best way forward.

|

|

Tech-speed commissioned their own electronics guru who came up with a very professional solution. Unfortunately, the unit cost was a staggering 100 quid per unit. On top of the price of a water pump and labour for installation, this approach was a financial dead-end. Fortunately, Will Munn's came to the rescue with a very cheap DIY electronic timer unit (circuit diagram shown below) that is switched on for a variable period by turning the ignition off.

All the parts can be bought for pennies from your local Maplins store or from the RS catalogue (see part numbers in the circuit diagram above) - and the result is pictured to the right, mounted inside the boot on the engine bay bulkhead wall. The variable time controller can be seen protruding enabling manual control over the delay period to switch off (from under 60 seconds to around 60 minutes) - and it works brilliantly, thanks Will!!!

So now we have a simple timer circuit controller - now to install the Davies Craig electric water pump...

The Davies Craig EWP in the MGF engine bay

The installation of the Davies Craig water pump actually proved to be very simple: the water pump was fitted exactly as the Bosch unit is fitted in the Lotus, in the by-pass circuit.

The EWP is fitted in the pipe from the the engine outlet stub to the bypass return pipe, as arrowed in the figure above (see the vertical red coloured pipe, coming down and then joining the bypass pipe in a T-junction).

This is shown a little better in the picture, left - the water pump is mounted just prior to the T-junction that runs from the heater circuit to the water rail that runs under the inlet manifold to the thermostat.

[The orange hose, by the way, is the air intake for my air filter induction system]

The result is a bypass circulator pump that is capable of circulating coolant after the ignition is switched off, and should, hopefully, prevent boiling and cavitation in the cylinder head. You'll note that the circulation is purely around the bypass circuit, and does not involve the radiator circuit - the reasoning being that by simply circulating the coolant will dissipate the heat in a greater volume of coolant and avoid the localised hot spots that can cause the damaging boiling.

The next step is to see whether heat is removed from the cylinder efficiently - more updates to come!!! The preliminary 'look and see' was performed at the Emerald Rolling Road, using an infa-red temperature sensing probe. Following a power run on the rollers, the probe was positioned at the cylinder head above the thermostat. Interestingly, without a pump, this area cools down fairly rapidly after the ignition is switched off. In contrast, with the water pump switched on, the head actually warms up in this position over a period of 10 or so minutes, before reaching a plateau and then slowly declining. The water pump is not transferring the heat to the coolant, so this heat must be from the cylinder head itself. So the first indication is that heat is being 'pumped' around the system. What remains to be determined is whether enough heat is being dissipated - and another question - might another pump for the radiator circuit be required if more heat is to be removed?