Or

Power shifts and the economy of movement

|

Words & Pictures: Rob Bell |

|

|

The Quick-shift comparison

tests Or Power shifts and the economy of movement

|

Introduction

“Driving n the setting in motion and controlling of a vehicle.”

This is a somewhat dry dictionary definition of an activity that all of us (we,

the merry band of MG enthusiasts and aficionados) spend a great deal of time and

energy undertaking and derive a great deal of pleasure from.

|

“The joy of Driving” is after all what sports cars are all about. There is

something almost indefinable about taking the helm of your MG (it makes not one

jot which one- they all have the same essential characteristics no matter when

or where they were built) – that special ‘something’ that makes you grin more

than a Cheshire cat that has had more than its fair share of cream and make

silly Mr. Toad utterances along the lines of ‘parp parp’. Or is that just me?

In my mind, there are a number of prerequisites to “joy through driving”; they

are all the usual things we enthusiasts always rave about- the car’s handling,

the engine’s power, how the induction and exhaust notes sound and most

importantly, how the car feels through its controls. A heady cocktail of these

ingredients are what makes barrelling down our favourite meandering stretch of

road such a joy.

The feel of the car through its interface with the driver really is

all-important; controversially one might regard the other aspects of the sports

car as secondary. An illustration of this point is the immensely enjoyable

Austin-Healey Sprite/ MG Midget. These are cars that are not over whelmed with

excessive power outputs from their modest A-series engines- yet this lack of

engine performance is ignored because the car ‘feels’ so right to drive- from

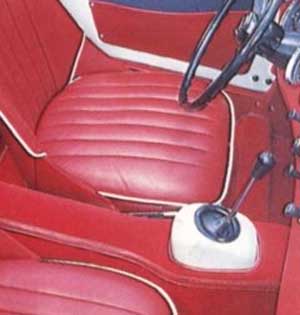

the feel through the steering to the snick-snick of the gear change (pictured -

the lever practically sprouts from the gearbox below). It is fun!

So the defining aspects of a good sports car in our ‘touchy-feely’ world of

automotive nirvana are the responses and feed back of the driver’s interface

with the oily bits of the car- the steering wheel, clutch, throttle and brake

pedals and the gear change.

What's the problem?

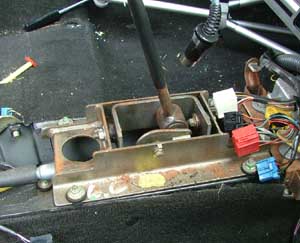

Pictured above, the standard selector mechanism, which works via a pair of cables to the gear box crank to select the gears. Play in the selector mechanism itself can lead to a sloppy-feeling gear-change. |

Ah yes, the gear change. The current MG roadster, the MGF, is a mid-engine car

in the current sporting doctrine classically espoused by Ferrari et al. Whilst

the configuration has massive benefits to areas such as innate handling balance and

grip, there is a potential downside: the gear linkage by definition has to be

long. Instead of the gear lever sprouting directly from the gear box without a

bush or connector rod to sully the feel of oiled cogs sliding over one another,

the mid-engine car has to have a long selector mechanism to re-locate the gear

lever into the cabin of the car (unless, of course, you know of a friendly

vertically challenged person who will happily sit in the dark enclosure of the

rear luggage compartment and swap cogs for you by command). Thus the feel of the

gear selection is largely lost through the absorption of movement through

compliant rubber bushes and long cables or rods. A remote gear change, if

executed poorly can lead to a rubbery and vague gearbox gate. Yuk. Instant

killjoy.

Fortunately, the MGF is already endowed with a surprisingly capable gear change

for a car with the engine located behind the driver’s ears. The standard change

is notably light, has tolerable precision and is easy to swap the cogs quickly

and accurately. Whilst one could never judge the MGF’s gear change to be up

there with the greatest, its single greatest attribute is that it does not

detract from the ‘fun’ that provides the ‘F’ in the MGF.

But there are options available to the MG enthusiast to significantly improve the gear selection process. To be quite honest, I had not even considered the options seriously until I was driving around the awesome Nürburgring in Germany. I was having a wail of a time on one of the most demanding and entertaining circuits in the world, with Paul Sharpe (one of the judging panel for this test) acting as co-pilot. Two things became very apparent: one- Porsche drivers don’t drive quickly enough and hold up MGs (maybe a price differential of 40 plus thousand pounds has something to do with it) and two, that on two separate occasions, on quick up-shifts to third, the gear selector would fail to slot smoothly into the gate. To this, Paul observed that maybe I should consider the Tech-speed Quick-shift kit.

Quick-shifts - a solution?

There are now several gear linkage options available for the MGF- either

“do-it-yourself” (with a hacksaw to reduce the length of the gear lever itself)

and professional conversions or kits from a variety of companies. As I was now

considering the potential purchase of such a kit, I for one wanted to try out

the available systems to determine which was best- an aim that was also shared

by a number of friends who were also very interested in finding out which option

suited them.

The common goal the manufacturers of the three gearshift kits share is a desire to provide the MGF with a faster, shorter throw and more accurate gear change. The gear change quality that these systems aspire to has been classically described as the ‘rifle-bolt’ action. What does this mean? It basically describes the sensation through the lever whilst the gear is being selected of a smooth mechanical action with a well-defined end-point: the sensation that you can actually feel the gear cogs intermeshing smoothly in a well-oiled fashion.

Therein lies part of the problem for someone trying to

describe a gear change modification- a lot of what is being attempted is based

purely on subjective perceptions. For this MG World test, we needed both

objective measures and subjective impressions- and to gain a better insight for

the latter we assembled a group of MGF enthusiasts who had mostly already taken

the decision to purchase a replacement gear selector kit.

The Gearshifts:

To provide a frame of reference we compared cars equipped with ‘quick-shift’

kits with a standard MGF, in this case, my 5-year-old example with 55 thousand

miles on the clock. There is a good reason for this- as the MGF gets older,

mechanical parts wear and soft rubber components perish. Therefore with an older

car, the potential gains from fitting a replacement gearshift kit are therefore

commensurately greater- and certainly many of the kit’s originators predict that

it is with the older cars where the majority of the market lies.

Against this lovingly abused example of the MGF, we pitched two brand-new MG show-room cars (kindly supplied to us for the day by the Farnham based MG specialists, Swain and Jones)- a standard 1.8i MGF and one of the limited edition MGF Trophy 160 models that has so impressed many road testers with its revised gear linkage.

Why compare a Trophy 160 gearshift with the pretenders to the ‘quickest gearshift’ crown? Whilst MG do not provide the Trophy system as an option or a kit of parts to interested MG enthusiasts, a motivated person with the sympathetic ear of someone in a MG dealership parts department would be able to find out the relevant part numbers and construct the kit themselves- so this is a theoretical contender in the quick-shift kit market (albeit one that MG-Rover themselves have yet to explore).

| What the kits involve: Mike Satur Slick Shift kit: A non- exchange kit incorporating fully assembled gear selector mechanism and replacement rose-jointed gearbox bell-crank for a DIY install. The angle and height of the gear lever are altered to give a more ergonomic feel and the gear box bell crank now has two positions for the joints to give as much adjustability as possible to ensure an easy and successful installation. Tech-speed Quickshift gear linkage kit: The installation involves the rebuilding of the existing gear selector mechanism to within the tightest production tolerance. Modifications are carried out to reduce the length of the gear lever itself and to modify the lever counterbalance. The rubber linkages to the selector cables are junked in favour of rose joints, and the gear box bell crank are also correspondingly modified. Quickshift Kit: The Quickshift kit is a non-exchange set of parts incorporating a chrome shortened gear lever with modified counter weight, and replacement gearbox and selector cranks designed to reduce the fore-aft movement of the gear lever. |

So much for providing the base line gear changes, now what about the gear change

kits that you can go out and buy? The competing comes from three separate camps.

In order of the age (in terms of market availability) of the kits they are the

following:

The gearshift test

As part of the objective for the replacement gearshifts was a snappier shorter

throw of the gear lever during gear changes, we undertook to measure the

distances between different gears. A short distance from first to second, second

to third and second to fifth provides some useful information as to how the gear

shift might feel when used for real in the road tests. The first to second shift

is representative of the wrist flick quick changes up and down the box- both

accelerating (first to second, and also the frequently used third to forth up

changes) and also down changes under braking into corners. The potentially

difficult second to third shift represents in addition the lateral spacing of

the gearbox gate- a tighter fore-aft and left-right spacing will be represented

in a shorter measured distance. The second to fifth change distance is used as a

measure of the total fore-aft left-right displacement of the gate- and obviously

is not a gear change that is used particularly frequently on the road!

You will notice in the results table that the movements are also shown as angles. There is a very good reason for this: many of the gearshift kits come with a shortened gear lever which confounds the absolute measures of gear lever movement. Fortunately, the ancient Greeks brilliantly foresaw our plight over two and a half thousand years ago and invented trigonometry. Thus the angles of movement provide a measure of the spacing of the gate independent of the length of the gearlever itself. This is important- if the only improvement to the shift’s throw is attributable to a shorter gear lever length, then the enthusiast might as well shorten the lever for him or herself and pocket the saving over the purchase and fitment of a gearshift kit.

At the same time as measuring the throw of the gear lever through the gate, we also made a measure of the accuracy of the gearshift mechanism, achieved by selecting first gear and measuring the side-to-side play and converting this measurement into an angle. The smaller the angle, the more accurate the feel of the gearshift- or at least that was our hypothesis.

The subjective component of the test took the form of a 15 to 20 minute road

test. Each of our testing panel drove each car equipped with each system we

wished to compare and wrote notes on each which were kept secret until the end

of the testing session. All discussion as to the perception of each kit was

strictly forbidden until all results were collated. A great deal of self control

was therefore exercised: stopping an MG enthusiast talking about MGs is

tantamount to stemming the flow of a river- and the release after the completion

of the road tests was surprisingly similar to breeching the dam in the

aforementioned analogy!

The results

|

Testing notes Standard 55 thousand mile gearchange

Trophy 160 (2500 miles)

Quickshift kit (approx 30 thousand miles on current linkage)

Mike Satur Slick Shift Kit (2000 miles)

[* It should be noted that the gear shift sold to customers is shorter than the one tested here] Tech-speed Quick shift kit (10,000 miles)

Tech-speed Quick-shift and Quick-clutch kit (5000 miles)

|

Moving to the results of the road tests first. Tom Randell had designed a particularly interesting and challenging road test circuit for us, which made us use all the gears frequently, both up and down the gate and to include both slow and gentle up and down shifts, and fast and furious shifts- i.e. using the gears to the full which was the sole purpose of the test.

Driving the older standard MGF first, I for one was in familiar territory. The gearshift felt pretty good. It wasn’t obstructive, and the lever action was light. Basically, it is a gearshift that goes about the job of swapping gears without fuss and without drawing much attention to itself. This was reflected again and again in the testers’ comments- basically inoffensive. But compared to the other systems the deficiencies became far more obvious.

Moving to a brand new current model year (2001) MGF, the increase in slackness in the older MGF’s gearshift was drawn into relief. The new car essentially had the same inoffensive gearshift, but the amount of free-play evident in the older car’s lever was noticeably reduced if not exactly absent. In comparison with the new car, the older system just felt baggy and loose. Whether this was due to improved production tolerances in the 2000 model year Mk2 MGFs, or whether this was simply the result of a well worn gear selector mechanism is was not immediately obvious (in fact later cars appear to have shorter gear levers)- but it certainly seems to lend credence to the assumption that the greatest advantage to the fitting of a quick-shift would have the greatest palpable result in older cars.

The Trophy 160 gearshift certainly felt excellent when compared to the standard

MGF. The shorter (than the older standard car’s) lever provides a shorter throw,

and as a whole felt a good deal more accurate when compared to that fitted in

the older of the standard MGFs. This shift was well received, although it was

soon to be shaded by the other gear linkages tested here.

But not, unfortunately, by the next gear linkage: this car was equipped with the

Quick-shift conversion. The car (affectionately called ‘Moggy’) is one of Swain

and Jones’ hard worked courtesy cars and has led a hard life. And it felt it.

The gear lever felt sloppy despite the lever’s diminutive length- in fact, if

one was not careful, selecting fifth or reverse could be rewarded with a harsh

metallic bang as the lever counter weight struck the transmission tunnel.

This is not always so, as I have driven other cars equipped with this gear change and even this very car earlier in its life and none are so afflicted as this. Less forgivable was the obstructive nature of the gear selector into third from second gear- it could take a couple of attempts to select third gear unless a particular technique is practiced. This characteristic has been present on this particular car from the conversion’s first flush of youth as I had the good fortune to drive this car soon after the kit was installed some two years ago. Even accepting the 30 thousand courtesy-car miles that this car has covered since the installation of the Quick-shift gearshift mechanism, such a reticence to select such a critical intermediate gear is a fatal flaw. The tester’s notes are unambiguous testimony to this observation: a universal thumbs down.

The two Tech-speed gearshift cars felt remarkably similar in the quality of the gear change. This was a welcome observation as it clearly indicates a high level of reproducible quality (both examples were customer cars which were not fettled for the purposes of this test). The stubby gearlever proved to be light and pleasingly precise through its movement through the gears. The feel through the lever was substantially more positive than that found in the standard MGFs, and significantly, was better than that system found in the MGF Trophy 160. Feedback through the gear lever was also substantially improved with the Tech-speed linkages; one could feel the beginnings of the sensation of the cogs being selected. Excellent. All the testers were extremely impressed, all rewarding the Tech-speed gearshift conversion extremely high marks and offering many complimentary comments. The clutch modification for the Tech-speed quick-shift kit proved to be more of a love or hate it. On the road, it had no impact upon the high quality of the gearshift- neither better nor worse, but the heavier clutch pedal was criticised by some of the testing team. It maybe that this is a conversion to be considered if you intend to undertake a lot of track work, either competitively or on track days; for the road the benefits in daily driving are probably minimal. If you are considering the clutch kit, then you should do some road testing of your own- the gearshift component however needs no such selling.

Mike Satur’s ‘Slick-shift’ conversion is the most heavily re-engineered kit

available here, something that is reflected in the price and is also reflected

in the feel of the gear selector mechanism. Where nylon bushes suffice in the

other conversions, Mike’s system uses phosphor-bronze joints- an indication of

the degree of ‘built to last’ engineering that has been invested into the design

of this system. As a result it feels the heaviest and the most mechanical. As

with the Tech-speed conversions, this system was fitted to a customer’s car, and

was set up to suit that particular customer’s tastes- to which read heavy. A

firm hand is required to move the lever through the gate, which in turn feels

noticeably defined. It is neither notchy nor inaccurate; it feels very

deliberate and mechanical. Undeniably head and shoulders better than the

standard fare (and far superior to the Quick-shift kit), the testing panel’s

opinion polarised over personal preference of light slick shifts like that

produced by Tech-speed or the heavier mechanical feel-some Mike Satur shift.

Nonetheless, the Mike Satur shift garnered universally high marks in the testers

notes.

The

Mike Satur Slick Shift The

Mike Satur Slick ShiftPictured right, the Mike Satur Slick shift (now in its MkIV version - the MkI was tested here in 1999) represents an extensive re-engineering of the standard gear lever mechanism, as hinted in the image. As such represents good value for money. |

The measurements

In terms of the throw of the gear lever through the gate, it is amazing what a difference a shorter gear lever will make. Equally as important, the impressions from our road tests appear to tally very well with the lever travel measurements. Easily the shortest gear lever tested here came supplied with the Tech-speed kit. At 170 mm, it is a full 30 mm shorter than the lever found on the Trophy 160 and 28 mm shorter than the Mike Satur Slick shift we tested. As a consequence, the in-gear movement was less with the Tech-speed kit than that found with the other gearshifts and the distances between gears through the gate were also much reduced. Based on this observation it is little wonder that the Tech-speed kit felt one of the most accurate and quick on the day (see the testers notes). The next most accurate system measured here was the Mike Satur Slick shift kit. There was notably little free play whilst the lever was in gear, and the gear-selection distances were less than that observed in the standard cars. This observation in itself is significant, and more so when one considers that the test car was equipped with a longer-than-usual gear lever (normal customer kits come with a lever of similar length to that found with the Tech-speed kit): the lever feels tight and accurate despite its length. This is reflected in the angles of movement, discussed further in the section below.

The Quickshift kit demonstrated an enormous amount of play, as can be seen in the figures- worse even than the 55 thousand mile standard MGF shift. In the most part this must be attributable to wear and tear- it would be very useful to repeat the test with a car equipped with a fresh kit with all the play adjusted out of the mechanism. If wear and tear was attributable to this kit’s poor performance, then unfortunately little useful conclusion can be drawn. With this caveat, in this company, it appears that the Quickshift offers no advantage at all to the gear lever throw.

The gearshift found in the new showroom MGF had a remarkably similar accuracy and throw to that found in the Trophy 160: the free play measures in particular being practically identical. This we found a little surprising, but does demonstrate that the standard gear shift is remarkably good out of the box. However, the Trophy holds some advantage insofar as it just beats the new standard shift by having a slightly shorter throw through and across the gate.

As was predicted, practically the worst gear shift here in terms of measured laxity in gear and distance traversed through the gate is that found on the 55 thousand mile MG. This provides us with two conclusions. First, if the worn system were simply rebuilt great gains could be reaped, and second, fitting of either one or the other of the Mike Satur or Tech-speed gear shift conversions would represent a fantastic improvement that would be immediately apparent to anyone driving the car.

Given that the length of the gear lever can have such a dramatic effect upon the perceived accuracy of the gear shift, what were the actual angles of movement? The result caused quite a surprise: the Tech-speed gear shift in fact has very similar angles of movement to that found in a brand new but standard gearshift. Having talked to the boffins at Tech-speed about their conversion, this actually comes as no surprise: when they rebuild the gear selector mechanism, they do so to MG production tolerances (albeit at the tightest range of these)- therefore to find nearly identical angles of in-gear play is to be expected. Similarly, the angle movement through the gear quadrants are remarkably similar to the standard set up. Thus, the ‘snappy’ feel of the Tech-speed Quick-shift gear linkage can largely be attributed to the shorter gear lever, although the snappy 1st-2nd shift is none-the-less tighter than these standard systems.

Easily the tightest gear shift kit- the one with the least lost motion in terms of angle movement in free play and through the gate quadrants, was the Mike Satur Slick shift. In fact, it was the only kit tested here that actually significantly reduced the angles of gear lever travel. In that the gear selector mechanism is so comprehensively engineered to remove slack, these results vindicate this approach. With a shorter gear lever- as that will be found on customer kits- the measures of distance traversed will be at least a match for that found on the Tech-speed kit.

As for the remaining gearshifts, similar comments apply to the measured movement distances- with the worst performances observed with the Quickshift and the worn standard shifts.

Summary of test raw data:

| Gear Shift |

in gear (mm) |

1st-2nd (mm) |

2nd-3rd (mm) |

2nd-5th (mm) |

lever length (mm) |

accuracy angle (degrees) |

1st-2nd angle |

2nd-3rd angle |

2nd-5th angle |

TOTAL ANGLES | TOTAL DISTANCES |

| Tech-speed | 21 | 93 | 112 | 127 | 170 | 7.1 | 31.7 | 38.5 | 43.9 | 121.2 | 332 |

| Mike Satur | 31 | 105 | 110 | 142 | 218 | 8.2 | 27.9 | 29.2 | 38.0 | 103.3 | 357 |

| Trophy 160 | 25 | 130 | 127 | 145 | 200 | 7.2 | 37.9 | 37.0 | 42.5 | 124.6 | 402 |

| Standard MY2001 | 42 | 128 | 145 | 166 | 220 | 11.0 | 33.8 | 38.5 | 44.3 | 127.6 | 439 |

| QuickShift | 56 | 130 | 135 | 164 | 215 | 15.0 | 35.2 | 36.6 | 44.8 | 131.6 | 429 |

| Standard Mk1 | 23 | 134 | 110 | 151 | 200 | 6.6 | 39.1 | 31.9 | 44.4 | 122.0 | 395 |

Conclusions

MG

World would like to thank… Swain and Jones (Kevin and Nick), for the supply of the Trophy 160 and

Quickshift equipped cars, and the measurements from a new show room MGF. Thanks

too to our testing panel who brought along their own cars to the testing

session: Paul Sharpe, Tom Randall (measurement grids, Swain and Jones

liaison, designer of the test route), Andy Phillips, and David Livingstone. Swain and Jones (Kevin and Nick), for the supply of the Trophy 160 and

Quickshift equipped cars, and the measurements from a new show room MGF. Thanks

too to our testing panel who brought along their own cars to the testing

session: Paul Sharpe, Tom Randall (measurement grids, Swain and Jones

liaison, designer of the test route), Andy Phillips, and David Livingstone. |

We have established that the standard gearshift system is quite a passable affair, but one that we have found to wear significantly with age. Whilst not exactly becoming recalcitrant, the replacement gearshift options represent a significant improvement over the standard system, and in fact represent an improvement over the already improved gearshift found on the Trophy 160. MG engineers, if you are reading this column, please take note.

The Quick-shift fitted to our test car represented a notable disappointment. Whilst obvious wear and tear has clearly taken its toll, it still has a worrying reluctance to select third gear that simply is not evident even on the standard gearbox. Moreover, if this is the typical pattern of wear over 30 thousand heavy handed miles, then perhaps this is not the most encouraging indication as to how the gearshift will cope with long term enthusiastic use. However, a new and properly adjusted gear linkage may transform this kit and we would very much like to sample such a kit before passing any further judgement.

Much better were the Tech-speed gear linkage kits (the gearshift alone and in combination with the clutch kit) and the Mike Satur gearshift kit. In fact, as soon as we started driving the cars it became rapidly apparent that this test would become a two horse race: both options are simply superb and the test panel could recommend either.

|

Who to contact and how much: Quick-shift kit: Brown and Gammons of Baldock. Cost £99.99 inc VAT excl. postage. Tech-speed Quickshift linkage kit: cost fitted, inc. VAT £188 Mike Satur Slick-shift: cost of kit, inc. VAT, excl. delivery £194. Prices correct at the time of writing; please check prices with suppliers at time of ordering. |

Interestingly, the character of the two systems could hardly be more different. This is genuinely surprising when one considers that the MGFs PG1 gearbox is completely unaltered in either conversion- remember this is a conversion purely of the gear linkage itself. So how to decide between them? Ultimately it boils down to a question of price, priorities and taste. If light, quick, positive and slick changes are your preference, then drop the lads at Tech-speed a line. The consistency of their work is legendary- a facet that endears great confidence in the long-term longevity of their work. That the price of the kit is all-inclusive makes it quite a bargain (£188 fitted and including VAT)- not to mention a very persuasive argument in its favour. Therefore if you are not in mind of ‘doing it yourself’ this could be the option for you. The Mike Satur kit also makes a wholly persuasive case for itself as well. As the lever angles indicate, this kit includes a thoroughly engineered selector mechanism, which to look one could easily imagine would last longer than the car itself. If you enjoy working on your car, the kit makes for a reasonably straightforward DIY proposition- easily completed within a day as it essentially consists of two ready-built up components. Certainly doing this will save significantly on labour charges, and takes the cost of the kit surprisingly close to that of the fitted Tech-speed linkage (cost before delivery is about £194). And then there is the sensation of the linkage. Yes, it does feel slightly slower than the Tech-speed linkage (but this to be fair is possibly just a trick of perception wrought by the increased weight and resistance in the lever’s movement) and a good deal heavier, but there are adjustments possible on the selector’s bearings and joints that would allow either Mike or the owner to make adjustments to suit their personal taste albeit to the detriment of the astonishing accuracy.

At the end of the day this choice is yours. Weigh up the need for accuracy, feel, weight, DIY or not to DIY, cost and finally how long you intend to keep the car and make your informed decision. We at MG World felt that both were highly recommendable. So, if you feel a need of a [gear] change, then it is good to know that your money can be spent with confidence in gearshift kits that actually do what their makers claim and do so with great competence. May the ‘Parp parp’ sentiment of Mr. Toad be forever with you…

|

Brown & Gammons 18 High Street Baldock Herts SG7 6AS Tel: 01462 490049 |

Tech-speed Motorsport The Mill Eathorpe Near Leamington Spa CV33 9DE Tel: 01926 632066 |

Mike Satur Unit 12, Mitchells Enterprise Park, Bradbury Baulk Lane, Wombwell, Barnsley, S Yorks S73 8HR Tel: 01226 750505 |

Swain and Jones 35/42 East Street, Farnham, Surrey GU9 7SW Tel: 01252 716201 |